Wood Wax Finish

THE PERFECT ALL-ROUNDER

Osmo Wood Wax Finish is a satin or satin-gloss wood finish which combines all the advantages of oils and waxes in one unique product. Resistant to water and dirt, very durable and smooths wood surfaces. Easy application – no need for a primer or sanding between coats, which saves time and money. Resistant against liquid spillages and the dry finish is safe for humans, plants and animals.

SPECIFICATIONS

Approx. Coverage

24-48m²/L (258-517 ft2/L) per coat

Number of Coats

1 coat = Transparent Color

2 coats = Intensive Color

Application Temp.

+5°C to 35°C

Approx. Dry Time

8-10hrs.

Sizes

5mL, .125L, 0.375L, 0.750L, 2.5L

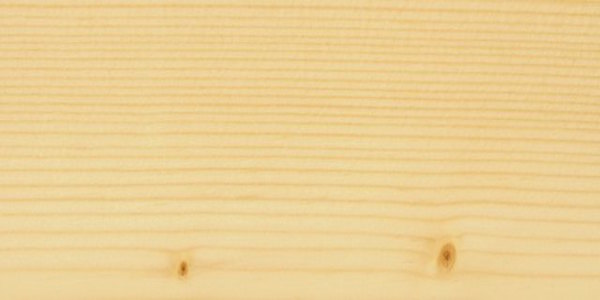

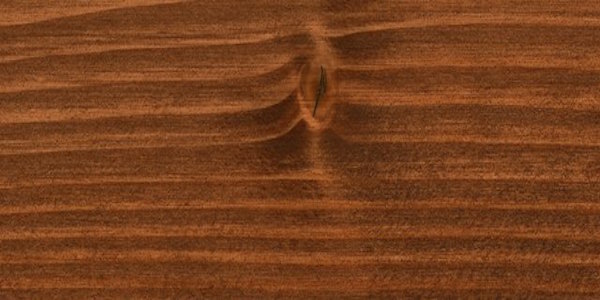

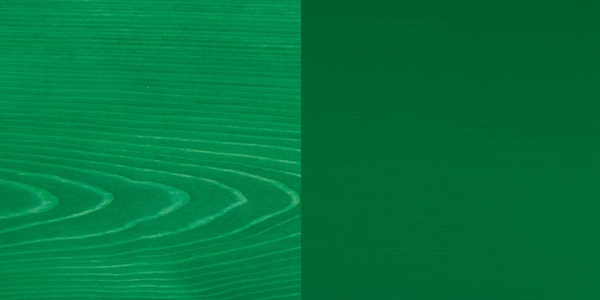

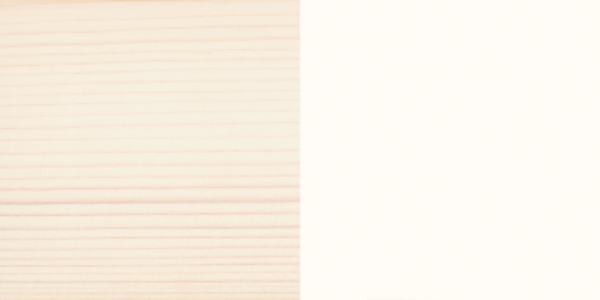

TRANSPARENT COLOR TONES

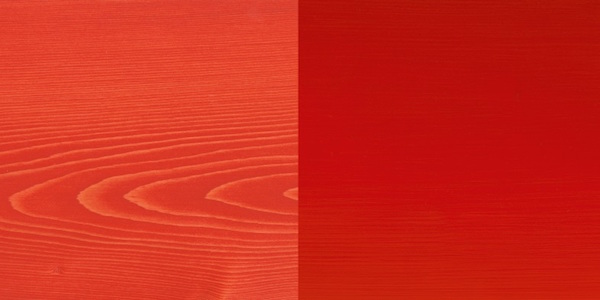

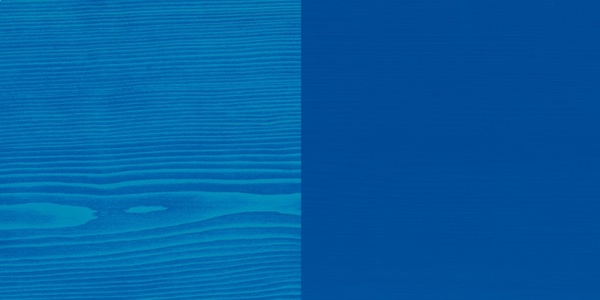

INTENSIVE COLOR TONES

APPLICATION INSTRUCTIONS

APPLICATION TOOLS

ADVANTAGES

- Suitable for all interior use

- Wood grain remains visible with transparent tones and wood grain can be hidden with intensive tones

- Very durable and hardwearing

- Water and dirt resistant

- Resistant to common liquid spillages such as water, juice, tea, cola and wine

- Saliva-resistant and sweatproof, suitable for children’s toys

- Microporous, breathable finish which does not crack, peel or flake

- No sanding necessary for spot repairs or future applications